Injection Molding

Custom Rubber Injection Molding Manufacturer

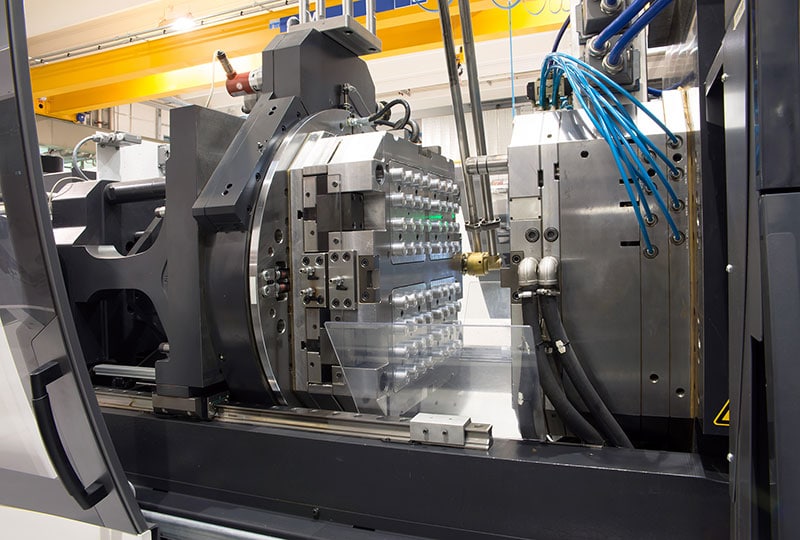

Lake Erie Rubber is a custom rubber manufacturer that specializes in rubber molding processes including injection molding. Our large injection presses give us the flexibility to produce a wide range of products for a variety of industries. This allows us to produce large parts or smaller parts in higher cavitation molds for improved cost and shorter lead times. Our stable, localized, and responsive supply chain reliably provides us with the supplies we need to keep lead times short and produce the best possible products. In addition, our engineering and design staff can provide high-quality technical and design support. With over 60 years of experience supplying components for OEM manufacturers and distributors, Lake Erie Rubber is your best option for custom rubber parts made in the United States.

We provide custom rubber injection molding to companies in many different markets, including the rail, mining, construction, vibration control, oil and gas, and pet product industries. Lake Erie Rubber has helped re-shore major programs that had been overseas for decades. We’ve done this by reverse engineering materials, developing new and more efficient tooling, and smoothly transitioning the supply of parts back to the United States. Our efficient and focused work has led to customers having drastically shorter lead times, improved technical support, and improved product quality.

When Should You Use Rubber Injection Molding Versus Other Manufacturing Processes?

Advantages

- Reduces piece price cost on mid to high volume components

- Good for high precision components

- Can accommodate over-mold or rubber bonded to metal or other material parts

- Flexibility for types of material to use

- Short cycle times

Disadvantages

- Higher initial tooling cost

What is Injection Molding?

Injection molding is a manufacturing process used for producing industrial parts. It is done by injecting material into a mold, where it stays for a set amount of time until it vulcanizes into its final shape. Injection molding can be done with many different materials, including rubber, metals, glass, and other materials. Lake Erie Rubber specializes in injection molding for rubber parts. Injection molding is often used for mass production of parts, where a part needs to be reproduced up to millions of times. This is because injection molding is a relatively quick, repeatable, and efficient process, and production costs are very low once the initial mold is created.

Industries Served

Injection molding is a manufacturing process used for producing industrial parts. It is done by injecting material into a mold, where it stays for a set amount of time until it vulcanizes into its final shape. Injection molding can be done with many different materials, including rubber, metals, glass, and other materials. Laker Erie Rubber specializes in injection molding for rubber parts. Injection molding is often used for mass production of parts, where a part needs to be reproduced up to millions of times. This is because injection molding is a relatively quick, repeatable, and efficient process, and production costs are very low once the initial mold is created.

Lake Erie Rubber serves a wide variety of different industries. These are just some examples of the industries we serve and what we provide for our customers:

- Rail Industry: Lake Erie Rubber manufactures custom rubber parts for the rail industry that are safe and compliant with government regulations. This includes bellows, cable cleats, electrical insulators, sand nozzles, and custom grommets.

- Mining: We serve companies across the mining industry by manufacturing rubber parts such as engine mounts, gaskets, flexible connectors, vibration isolators, bumpers, and much more.

- Construction: Lake Erie Rubber provides custom rubber parts for applications in the rail industry, including bellows, grommets, gaskets, bumpers, and more.

- Vibration Control: We provide rubber parts for applications in vibration control, including a variety of mounts, spring cups, bushings, anti-vibration pads, and more.

- Oil & Gas: In the oil and gas industries, Lake Erie Rubber provides custom rubber parts including gaskets, grommets, seals, and more.

- Pet Products: Lake Erie Rubber manufactures safe products for your pets, including an assortment of dog toys. All of our pet products are safe, using only FDA-compliant ingredients. We also provide full service capabilities, including design, manufacturing, and packaging services.

Contact us today for a free estimate.

"*" indicates required fields