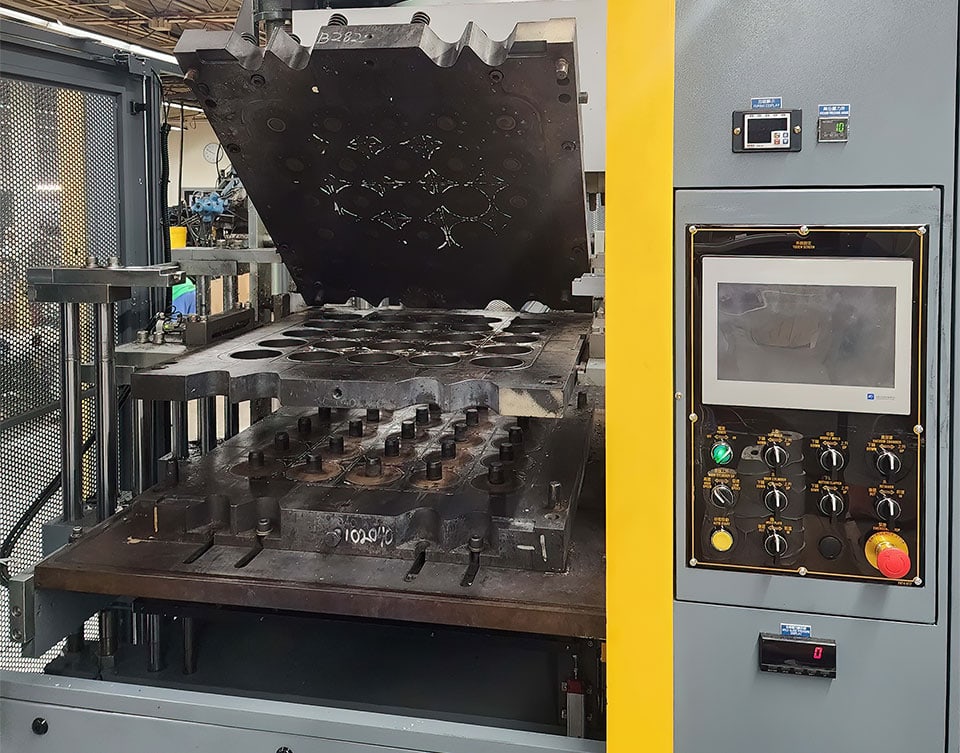

Transfer Molding

Custom Rubber Transfer Molding Manufacturer

Lake Erie Rubber is a rubber transfer molding manufacturer based in Erie, PA. We specialize in a variety of rubber molding services, including transfer molding, compression molding, and injection molding. With over 60 years of experience manufacturing rubber parts for OEM manufacturers and distributors, we have mastered the transfer molding process – often used for manufacturing colored rubber components or precise parts. We work quickly and efficiently to produce the best custom rubber parts, right here in the United States. Our stable, localized, and responsive supply chain allows us to provide top-quality products with very short lead times, and to offer you high-level technical support in material selection, design for manufacturability, and tooling design.

We provide rubber transfer molding services to companies across the U.S. that operate in a wide variety of industries. These industries and applications include rail, mining, construction, vibration control, insulation, oil and gas, and pet product industries. We have been able to create specialized parts for customers who had been unable to find them anywhere else, meeting all of their specifications and doing so with a quick turnaround time. Whether it’s developing a specific type of material or simply lowering production costs, Lake Erie Rubber will create a specialized solution that fits your needs while keeping costs low.

When Should You Use Rubber Transfer Molding Versus Other Manufacturing Processes?

Advantages

- Good for high precision applications

- Can accommodate over-mold or rubber bonded to metal or other material parts

- Good for colored compounds of rubber

Disadvantages

- Labor intensive compared to injection molding

- Higher tooling costs than compression tools

What is Rubber Transfer Molding?

Transfer molding is a manufacturing process used for creating various industrial products. It is done when a piece of uncured rubber called a preform is loaded into a transfer pot. The ram is then closed, pushing the preform through the runner and gate system into the part cavity. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape. While it is more labor intensive than injection molding, transfer molding is ideal for high precision applications, as well as for using colored rubber compounds.

Industries Served

Lake Erie Rubber serves a wide variety of different industries. These are just some examples of the industries we serve and what we provide for our customers:

- Rail Industry: Lake Erie Rubber manufactures custom rubber parts for the rail industry that are safe and compliant with government regulations. This includes bellows, cable cleats, electrical insulators, sand nozzles, and custom grommets.

- Mining: We serve companies across the mining industry by manufacturing rubber parts such as engine mounts, gaskets, flexible connectors, vibration isolators, bumpers, and much more.

- Construction: Lake Erie Rubber provides custom rubber parts for applications in the rail industry, including bellows, grommets, gaskets, bumpers, and more.

- Vibration Control: We provide rubber parts for applications in vibration control, including a variety of mounts, spring cups, bushings, anti-vibration pads, and more.

- Oil & Gas: In the oil and gas industries, Lake Erie Rubber provides custom rubber parts including gaskets, grommets, seals, and more.

- Pet Products: Lake Erie Rubber manufactures safe products for your pets, including an assortment of dog toys. All of our pet products are safe, using only FDA-compliant ingredients. We also provide full-service capabilities, including design, manufacturing, and packaging services.

Contact us today for a free estimate.

"*" indicates required fields