Rubber Molding Manufacturer of Custom Parts

Injection Molding

Compression Molding

Transfer Molding

Rubber Mold Tooling

Lake Erie Rubber, a Custom Molding Manufacturer

Lake Erie Rubber is a custom rubber manufacturing company that was started in 1961, specialized in rubber injection molding, transfer molding, and compression molding. We manufacture custom rubber components for the rail, construction, building vibration isolation, and oil and gas industries. In addition to the industrial sector we have experience in the designing and manufacturing of custom made rubber pet toys. Our goal is to grow Lake Erie Rubber to continue to improve the pay and benefits for our current employees, add more new jobs in Erie, and to be an Erie community asset.

Trusted by Industry Leaders

Injection Molding

Injection Molding is when an uncured rubber strip is fed through a screw barrel into a heated, closed mold (the mold is specific to the part and may have multiple cavities). The screw pushes a measured amount of rubber through a system of gates and runners into the cavities. The pressure of the press holds the mold closed. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape.

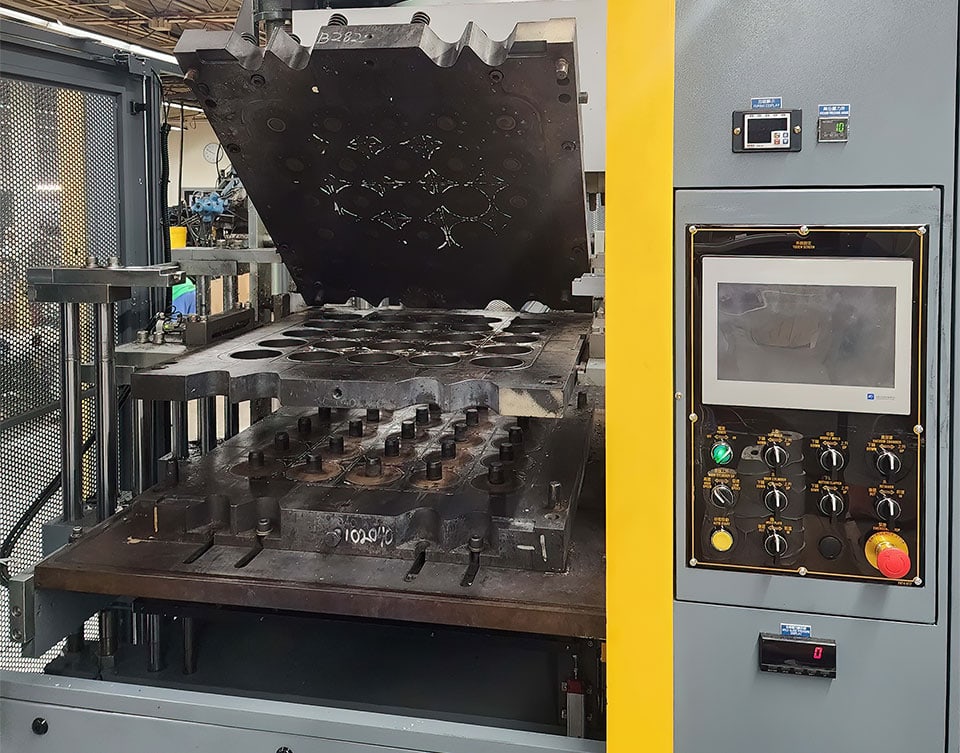

Compression Molding

Compression molding is when a preform (specific size and weight of uncured rubber) is placed into the open mold. The heated mold (specific to the part) is then closed using hydraulic pressure. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape.

Transfer Molding

Transfer Molding is molding is when a preform (specific size and weight of uncured rubber) is placed into the transfer pot. The ram is then closed pushing the uncured rubber through the runner and gate system into the part cavity. The pressure of the press holds the mold closed. The rubber is held in the heated cavity for a specific amount of time to properly cure the rubber into its final shape.

Rubber Mold Tooling

Lake Erie Rubber helps clients with material specifications, testing and validation, design for manufacturing, 3D printed prototyping, and product development. We have experience helping customers take an initial idea to a 3D prototype, and then to a finished product. This includes selecting the best material for the application, the appropriate molding process, and mold design. Lake Erie Rubber can also reverse engineer an existing product and develop a manufacturing plan for production.

Value Added

Speed

Our entire team is focused on being quick to respond to our customers requests from product development to expediting production orders.

Quality

We only use thoroughly vetted and proven U.S. based suppliers for our raw materials and molds, in conjunction with our advanced digital QMS, to guarantee great performance and quality in the products we manufacture.

Technical Expertise

We understand that most customers do not have elastomer experts in house, so we offer support with design for manufacturing, material development, product development, material testing, and more.

client testimonials

Contact us today for a free estimate.

"*" indicates required fields