Rubber Molding for the Power Generation Industry

Rubber Molding for the Power Generation Industry

With three styles of rubber molding performed at Lake Erie Rubber and decades of experience serving OEMs, we are well-suited to even the most complex power generation industry needs. We can mold rubber vibration control components for power generation equipment. Our team can also serve as your American based medium to high volume manufacturer for injection molded rubber parts for power generation equipment. We utilize state-of-the art compressions, transfer, and injection molding equipment, digital quality management tools, and employ a skilled staff of molding experts.

As you continue reading, you can gain a better understanding of the power generation rubber molding work performed at our Erie, PA facility. After doing so, we want you to reach out to begin a discussion and allow us to quote your next rubber molding production run.

US Based Compression Molding Solutions

Ensure quality and prompt turnaround time for your compression molded rubber power generation parts by contracting Lake Erie Rubber to manufacture them. From working with established US raw material suppliers to utilizing advanced digital QMS tools, we focus no quality throughout every step in the molding process. As a US-based rubber compression molding company, we find it valuable to maintain oversight of our process in its entirety. At no point in the course of a molding job completed here will there be room for material issues or molding flaws that will not be spotted prior to delivery. We know power generation industry OEMs value quality and prompt molded part delivery and we ensure it on each job.

Re-shore You Rubber Power Generation Products Business with Expert Help

In recent years, Lake Erie Rubber has become a go-to resource for manufacturers seeking to re-shore manufacturing operations. With our US-based rubber molding operation and consistent supply chain, we can provide your power generation business with the consistency your operation demands. Depending on the rubber parts you need produced, we can perform molding ranging from low to high volume and this includes custom repeat production work. If re-shoring is something you would benefit from but need to find the right partner prior to bringing your production back to the US, we are ready to serve your needs for rubber molding for the power generation industry.

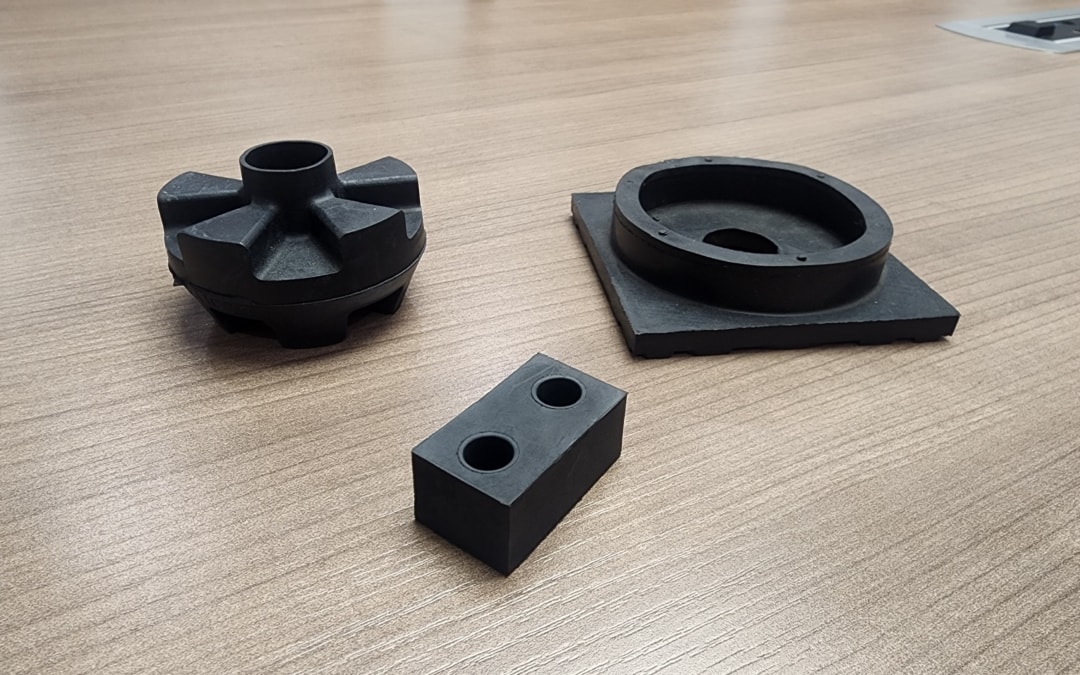

Lake Erie Rubber Molds Parts for Electrical Insulation, Cable Protection, and Vibration Control

Lake Erie Rubber understands the requirements for electrical isolation components, high voltage cable protection components, and vibration isolators for power generation equipment. We are experienced in molding parts including electrical isolators, cable cleats, grommets, anti-vibration pads, mounts, bushings, and more. Lake Erie Rubber can verify electrical insulation requirements on site if needed. Given the nature of power generation, equipment can be prone to vibration. While the right base plate can be crucial to securely anchor power generation machinery, vibration control is also important. Rubber molded vibration control parts made here can help keep your or your customers power generation equipment in place and reduce unnecessary sound in their industrial environment. To learn the full suite of rubber vibration control products we can mold for you, contact our team to start a discussion.

Order Rubber Molded Gaskets, Seals, and More

In addition to power generation equipment, Lake Erie Rubber has experience making parts that are involved in protecting energy extraction equipment. For example, if your OEM serves the oil and gas industry you can turn to us for rubber molded grommets, seals, gaskets, and more. We can utilize our trusted material suppliers to provide us with the perfect type of rubber to use for your part. This versatility adds to our ability to perform a wide variety of rubber molding for the power generation industry.

Custom Rubber Injection Molding Solutions for Power Generation Businesses

We have a 60-year history of supplying custom rubber injection molded parts to OEMs in a diverse variety of industries including power generation. This is why we have developed the ability to perform rubber molding work in three different styles. Depending on the complexity of the parts you need and the volume of production your contract will require, one of these methods will be the right fit. Whether you contract Lake Erie Rubber for compression, injection, or transfer molding we will complete your work promptly and ensure that the price we charge is as competitive as possible.

We are seeking to form long-term relationships with OEMs and want to be the manufacturer you turn to for rubber molding for the power generation industry.