Rubber Overmolding: Rubber to Metal Bonding Manufacturers

Rubber Overmolding: Rubber to Metal Bonding in Erie, PA

Lake Erie Rubber is a customer rubber manufacturer based in Erie, Pennsylvania that specializes in injection molding, transfer molding, and compression molding. With over 60 years of experience, we have become an industry leader and have the expertise to manufacture custom parts for many different industries. Among our many capabilities is rubber to metal bonding and overmolding, the process that allows us to manufacture specific parts with rubber to metal bonding. We use rubber overmolding to manufacture a wide range of products for customers in the industrial space.

What is Rubber Overmolding?

Rubber overmolding is a process that involves encapsulating a substrate, called an insert, with rubber during the injection molding process. First, the insert, often made from metal, is placed inside the mold cavity. The mold is then injected with rubber, effectively surrounding and covering the substrate. The finished product is a part that is a combination of substrate and rubber bonded together. Rubber overmolding allows for the creation of more complex products by combining different materials together, providing additional functionality or aesthetic appeal to a finished product.

Mechanically vs. Chemically Bonded Rubber

The rubber overmolding process can utilize either mechanical or chemical bonding. Parts can also be designed to use both mechanical and chemical bonding. Lake Erie Rubber specializes in both mechanically and chemically bonded rubber overmolding. Each of these processes has its advantages and disadvantages, and which method is used may depend on various factors.

In mechanically bonded overmolding, the rubber is molded directly to the substrate by utilizing a mechanical interlock with the surface. Ridges or grooves are used as interlocking features to create a stronger bond with the rubber. This process is relatively simple and straightforward. However, the strength of a mechanical bond is generally not as strong as a chemical one.

Chemically bonded rubber overmolding uses a chemical bonding agent as an adhesive to bond the rubber to the substrate. This bond is exceptionally strong, often surpassing the strength of the rubber material itself. This type of bonding is used when a high strength bond is needed, and while it creates a stronger bond than mechanically bonded overmolding, it requires careful preparation, precision, and attention to detail to be done correctly. While competitors may cut corners in this initial phase of the process, we understand that preparation is a crucial step in ensuring that the strongest possible bond is formed.

Choosing the right overmolding method will depend on the specifics requirements of your part and its application. Both mechanically and chemically bonded overmolding have their advantages and consideration. At Lake Erie Rubber, our team will work closely with you to discuss your unique requirements and ensure that we select the right process when manufacturing your parts.

Benefits of Rubber Overmolding

Rubber overmolding offers many benefits that make it a popular technique for rubber manufacturing. Its main benefit is that it easily allows for the combination of different materials, such as metal or plastic, with rubber through injection molding. This allows for the integration of many different characteristics into one part, meaning a part can have the rigidity and sturdiness of metal, while having the vibration isolation or shock absorption of rubber. Utilizing rubber also allows for the creation of parts that are airtight, waterproof, and shock absorbent. Rubber overmolding is also a very cost effective process, making it a common choice for producing high quality and affordable parts.

Common Applications of Overmolded Products

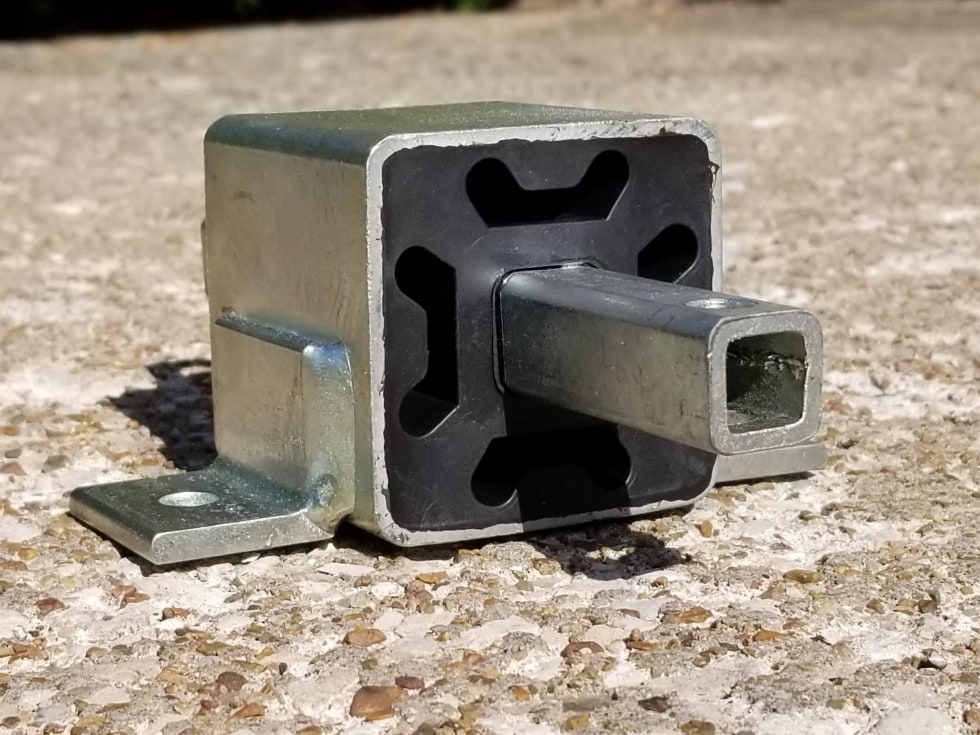

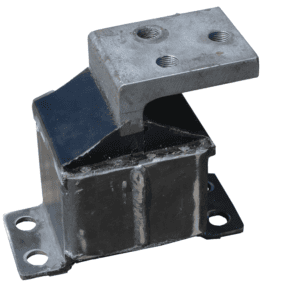

Rubber overmolding is used for manufacturing rubber parts in a variety of different industries. At Lake Erie Rubber, we specialize in creating parts for use in industrial applications. This includes industrial bumpers, often used for a range of doors and cabinets; engine mounts for off-highway mining trucks; and silicone plates for sand casting.

While we specialize in industrial applications, we have the capabilities to manufacture parts for a variety of other industries. For example, we recently made rubber javelin tips as many high schools have outlawed metal tipped javelins. We created an overmolded metal piece that makes the javelin tail more rigid. Regardless of the industry you’re in, you can get in touch with us to learn more about our rubber overmolding capabilities to see if we can still help with the manufacturing of your products.

View the photos below of some of our rubber overmolded products:

Lake Erie Rubber’s Overmolding Services

Lake Erie Rubber provides custom rubber overmolding solutions for a variety of products and applications. Our team of experts will ensure that we take the time to assess your specific requirements in order to determine the optimal bonding method, whether it be mechanical or chemical overmolding. Moreover, we will help guide you through the process of choosing the right materials and substrate for your part. When it comes to chemical overmolding, what sets us apart is our commitment and precision with regard to the metal preparation process. Contact us today to learn more about how we can help you with all of your rubber manufacturing needs.