What is EPDM Rubber? Properties, Applications, & Uses

What is EPDM Rubber?

Ethylene propylene diene monomer, or EPDM, is a type of synthetic rubber that is commonly used across many industries. Developed in the early 1960s, it is made from ethylene, propylene, and diene monomers and is a very versatile and durable type of rubber with many applications. While natural rubber may deteriorate with exposure to sunlight and ozone and become brittle over time, some synthetic rubbers like EPDM are designed to be able to withstand more extreme conditions and can last much longer.

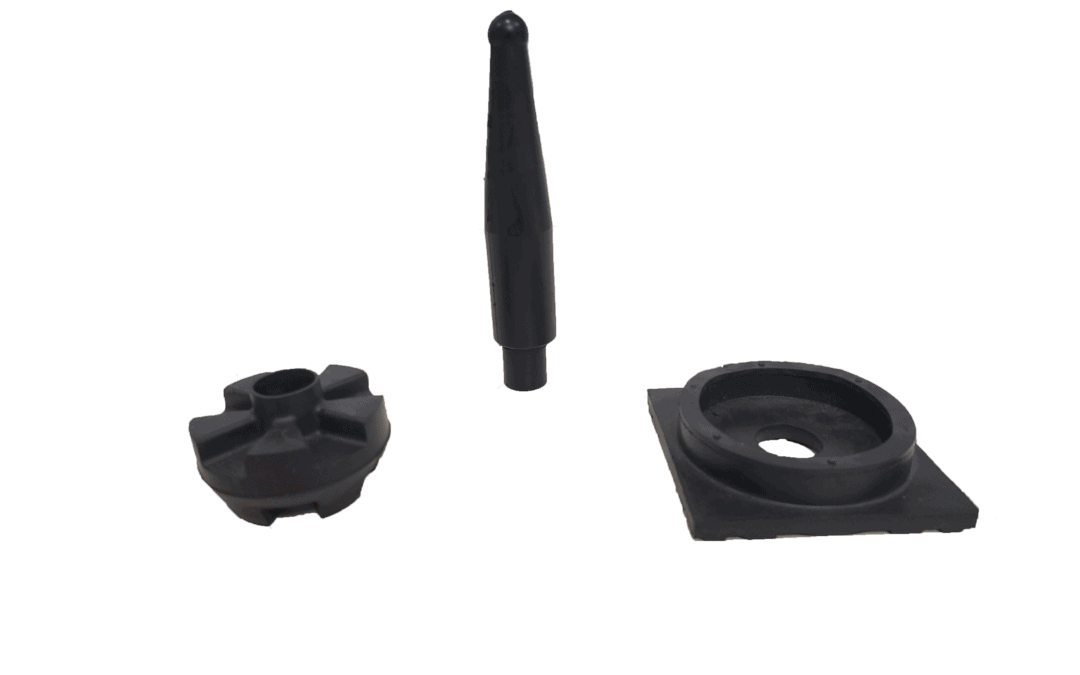

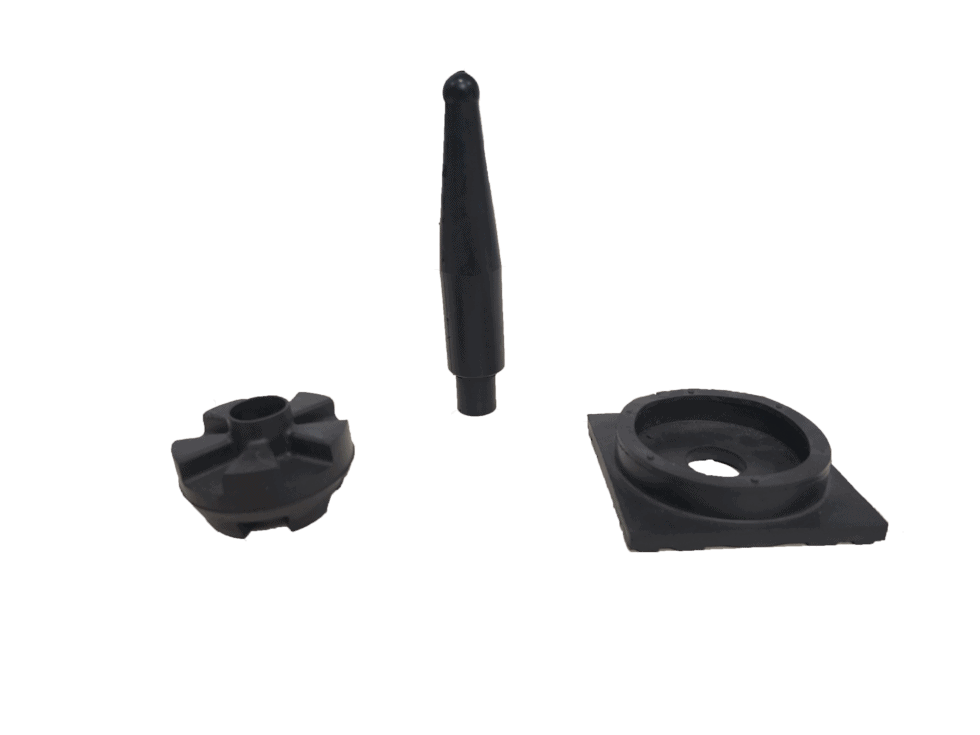

EPDM has many applications due to its durability, flexibility, ability to withstand a wide range of temperatures, and many other properties. This includes flexible connectors, water gaskets, O-rings, grommets, and a variety of automotive parts, as well as many other outdoor applications. It is also the only rubber that is used for making full roofing systems.

Properties of EPDM Rubber

There are many advantageous properties of EPDM that make it a great choice for many applications. There are, as with any polymer, disadvantages as well. Be sure you understand all of the pros and cons of EPDM before choosing it for your application.

Advantages

EPDM is durable, flexible, and resistant to UV exposure, ozone, aging, weathering, acids, and many other chemicals. It is also one of the most water-resistant rubber materials. This durability makes it a very common choice for many different outdoor applications. Additionally, unlike many other types of rubber, it does not bloom, meaning its color doesn’t fade when exposed to the elements. EPDM can last for decades if properly taken care of.

EPDM also has a very wide temperature operating range. It can withstand temperatures as low as -60°F(-51°C), and as high as 350°F(177°C). Unlike many other polymers, it can be exposed to a range of cycling temperatures and will not degrade. EPDM also processes well for injection, compression, or transfer molding.

Disadvantages

EPDM is one of the best rubber polymers, but it still has its disadvantages. While it does well in extreme temperatures, it does not possess good flame resistance. It also does not have good resistance to mineral oils or petroleum oils. If exposed to these elements for an extended period, EPDM will deteriorate. It is also difficult to make a strong rubber-to-metal bond with EPDM.

Common Applications of EPDM Rubber

EPDM is one of the most commonly used rubber polymers and has a wide range of applications. As previously stated, its durability and overall ability to withstand the elements make it a great choice for many outdoor applications. Some examples of EPDM applications include:

- Automotive – EPDM is used for many different car parts, including seals for doors and windows, brake systems, bumpers, windshield wipers, and various hoses and tubes.

- Locomotive – EPDM is used to make flexible connectors used in locomotives. Its flexibility, temperature resistance, resistance to ozone, and resistance to weathering mean it can last a long time.

- Construction – EPDM is used for roofing, sealants, garage door seals, pool liners, and many other applications in construction.

- Industrial – EPDM is used for water gaskets, O-rings, grommets, electrical insulation, and weather stripping.

Contact Us Today

EPDM is one of the most commonly used rubbers, and maybe the right choice for your application. Contact us today to see how we can help you make the best choice possible for your needs.