What is Nitrile Rubber (NBR)? Properties, Applications, & Uses

What is Nitrile Rubber (NBR)?

Nitrile butadiene rubber (NBR) is a commonly used synthetic rubber elastomer, with applications across many different industries. Developed in Germany in the 1930s, it is known for its strong resistance to oil, fuel, acids, and other chemicals, making it ideal for a range of automotive and aerospace applications. NBR is a copolymer made from two polymers: acrylonitrile and butadiene. Specific properties of NBR can vary based on its chemical composition. Higher amounts of acrylonitrile will lead to better oil resistance, but also decrease its flexibility. NBR has many applications across many industries due to its resistance to oil and chemicals, its wide temperature operating range, and abrasion and tear resistance.

Properties of Nitrile

NBR has many advantageous properties that make it a good choice for many different uses across many different industries. As with any material, there are also some downsides which may make it less than ideal for your specific application. Be sure you understand all of the advantages and disadvantages of NBR before choosing it for your specific project. Learn more about choosing the right rubber for your manufacturing needs.

Advantages

NBR has an unusually strong resistance to oil, gasoline, acids, aliphatic hydrocarbons, and other chemicals. It also has a wide temperature operating range of -40°C (-40°F) to 108°C (226°F). The combination of these two strong characteristics make nitrile the perfect choice for use in the automotive and aerospace industries. NBR also has strong water resistance, as well as good abrasion and tear resistance.

Disadvantages

No material is perfect, and NBR is no exception. Like any other elastomer, NBR has its disadvantages. When compared to natural rubber, NBR is not a strong or flexible material. Additionally, it has poor weathering resistance, and is not very resistant to sunlight, ozone or aromatic hydrocarbons. This means that it would not be an ideal choice for any outdoor applications.

NBR may still be the right choice for your specific needs. Its advantages still outweigh its disadvantages, and depending on the application, will still be a great choice of material. You’ll need to weigh all of the pros and cons when deciding what rubber to choose for your specifications.

Common Applications of Nitrile

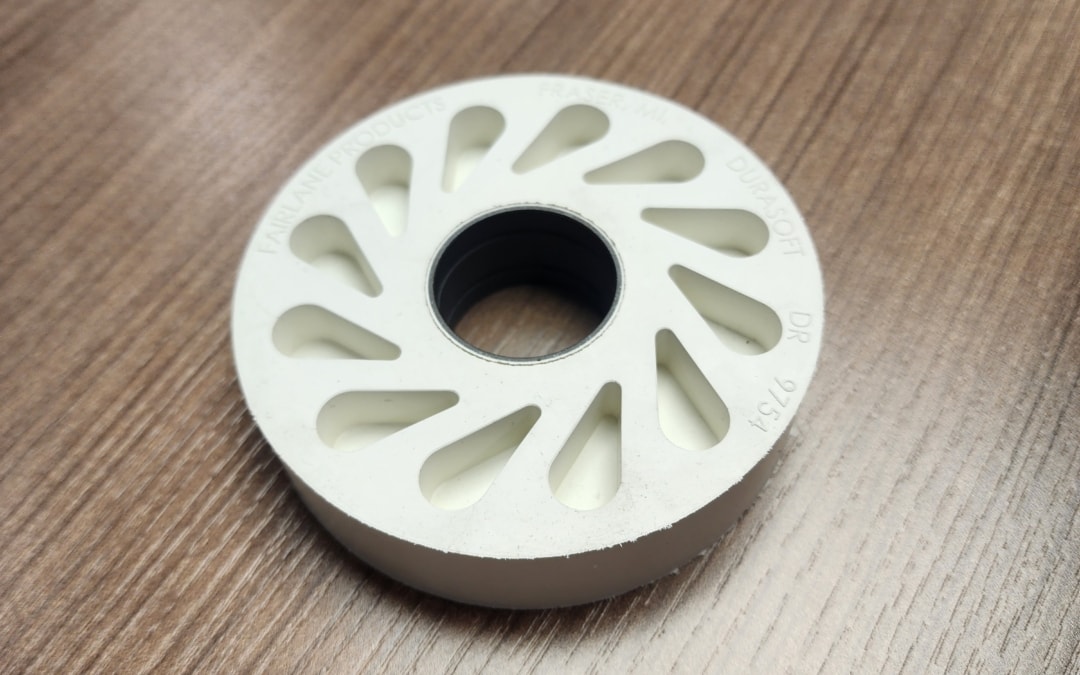

Nitrile is one of the best synthetic rubber materials, and as such is used for many different purposes in many fields. It is used for seals, hosing, tubing, gaskets, grommets, adhesives, sealants, and more in a wide range of industries. Additional applications of NBR include:

- Automotive. Due to its strong resistance to oils and fuels, NBR is commonly used in oil hoses, seals, grommets, and more in the automotive industry.

- Aerospace. Just as with the automotive industry, NBR’s fuel, oil, and chemical resistance makes it ideal for fuel and oil oses, seals, grommets, and fuel tanks.

- Gloves. Disposable nitrile gloves are commonly used throughout the medical industry for examinations, as well as for cleaning. More heavy-duty, reusable gloves are also used for nuclear applications.

Contact Us Today

Nitrile is high quality synthetic rubber and may be the right choice for your specific application. Get in touch with us today to see how we can help you make the right choice for your specifications.